Understanding the Allen-Bradley 509 Starter Wiring Diagram is a crucial step for anyone working with industrial motor control systems. This diagram serves as the blueprint, guiding the safe and efficient connection of components to ensure your motor operates as intended. Whether you're a seasoned electrician or just beginning to explore motor control, grasping the specifics of the Allen-Bradley 509 Starter Wiring Diagram will significantly enhance your ability to troubleshoot, install, and maintain these vital systems.

The Heart of Motor Control: What is an Allen-Bradley 509 Starter Wiring Diagram?

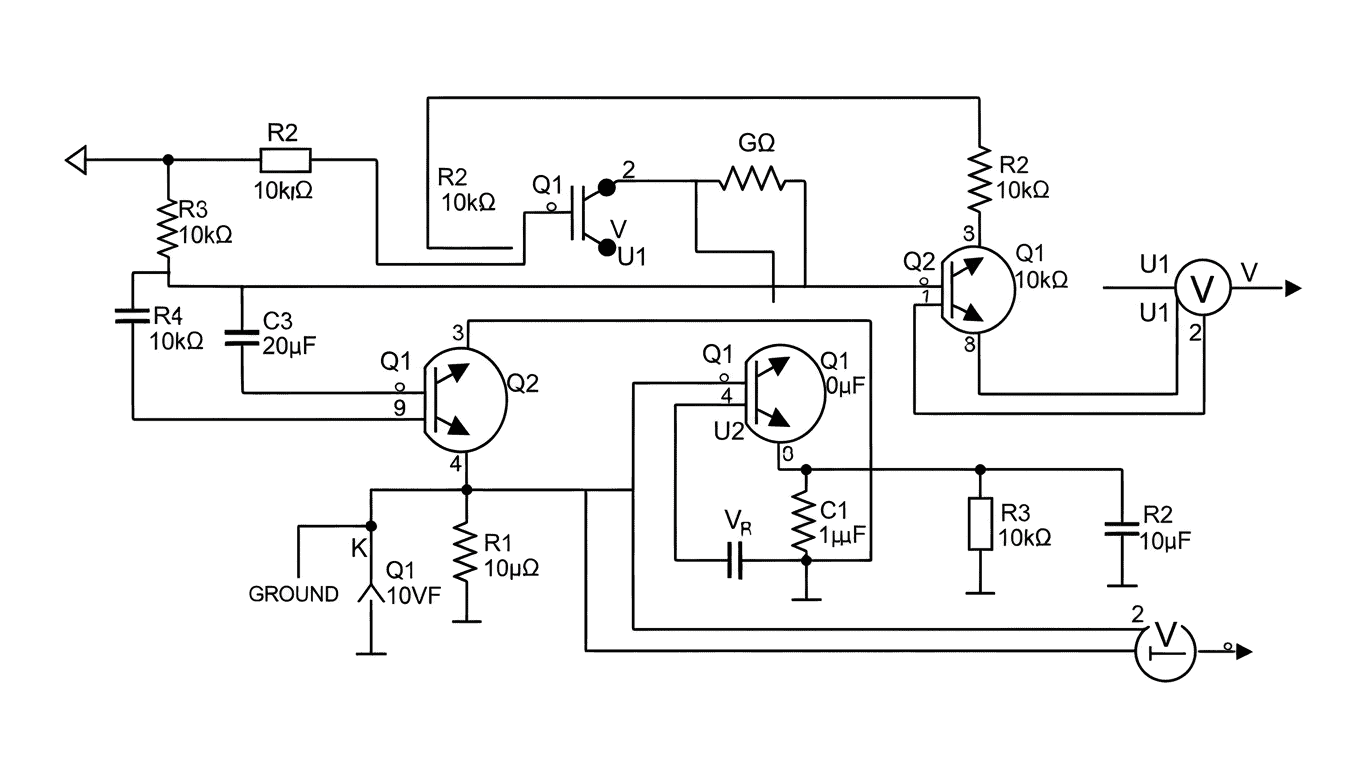

At its core, an Allen-Bradley 509 Starter Wiring Diagram is a schematic representation that illustrates how all the electrical connections are made for a specific motor starter. The Allen-Bradley 509 series is a widely used line of combination motor starters, meaning they integrate a circuit breaker or fuse with a motor starter (contactor and overload relay) in a single unit. This diagram is not just a collection of lines; it's a precise language that shows the flow of electricity, the purpose of each terminal, and the relationship between different components. The importance of a correct Allen-Bradley 509 Starter Wiring Diagram cannot be overstated, as it directly impacts safety, operational reliability, and the longevity of your motor and associated equipment.

These diagrams are essential tools for a variety of tasks. When installing a new motor starter, the wiring diagram ensures that all connections are made to the correct terminals, preventing short circuits, incorrect phasing, or improper operation. During maintenance or troubleshooting, the diagram acts as a guide to identify potential issues. For instance, if a motor isn't starting, the diagram helps trace the power path to pinpoint where the electrical signal might be interrupted. Here’s a breakdown of typical components you’ll find referenced:

- Control Circuit Wiring

- Power Circuit Wiring

- Overload Relay Settings

- Auxiliary Contacts

The Allen-Bradley 509 Starter Wiring Diagram can vary slightly depending on the specific model, enclosure type, and optional accessories. However, the fundamental principles remain consistent. You will typically find distinct sections for the power wiring and the control wiring. The power wiring section illustrates how the incoming power lines (L1, L2, L3) are connected to the overload relay and then to the motor terminals (T1, T2, T3). The control wiring section details how the coil of the contactor is energized, often through a start/stop button configuration, and how the overload relay can trip the control circuit to stop the motor in case of an overcurrent condition. Below is a simplified representation of common terminal designations:

| Component | Typical Terminals |

|---|---|

| Incoming Power | L1, L2, L3 |

| Motor Connection | T1, T2, T3 |

| Control Coil | A1, A2 |

| Overload Reset | Various, often indicated by a button or terminal |

For those seeking to gain a deeper understanding or requiring the specific schematics for a particular 509 starter model, referring to the official documentation provided by Rockwell Automation (the manufacturer of Allen-Bradley products) is the most reliable approach. These resources offer detailed, model-specific wiring diagrams.