Understanding an Alternator Into Generator Wiring Diagram is crucial for anyone looking to repurpose automotive alternators into standalone power generation units. This process involves more than just connecting a few wires; it requires a fundamental grasp of how alternators work and how to adapt them for continuous power output. Whether you're a hobbyist seeking to build your own backup power source or a student exploring renewable energy, this guide will demystify the Alternator Into Generator Wiring Diagram.

What is an Alternator Into Generator Wiring Diagram and How is it Used?

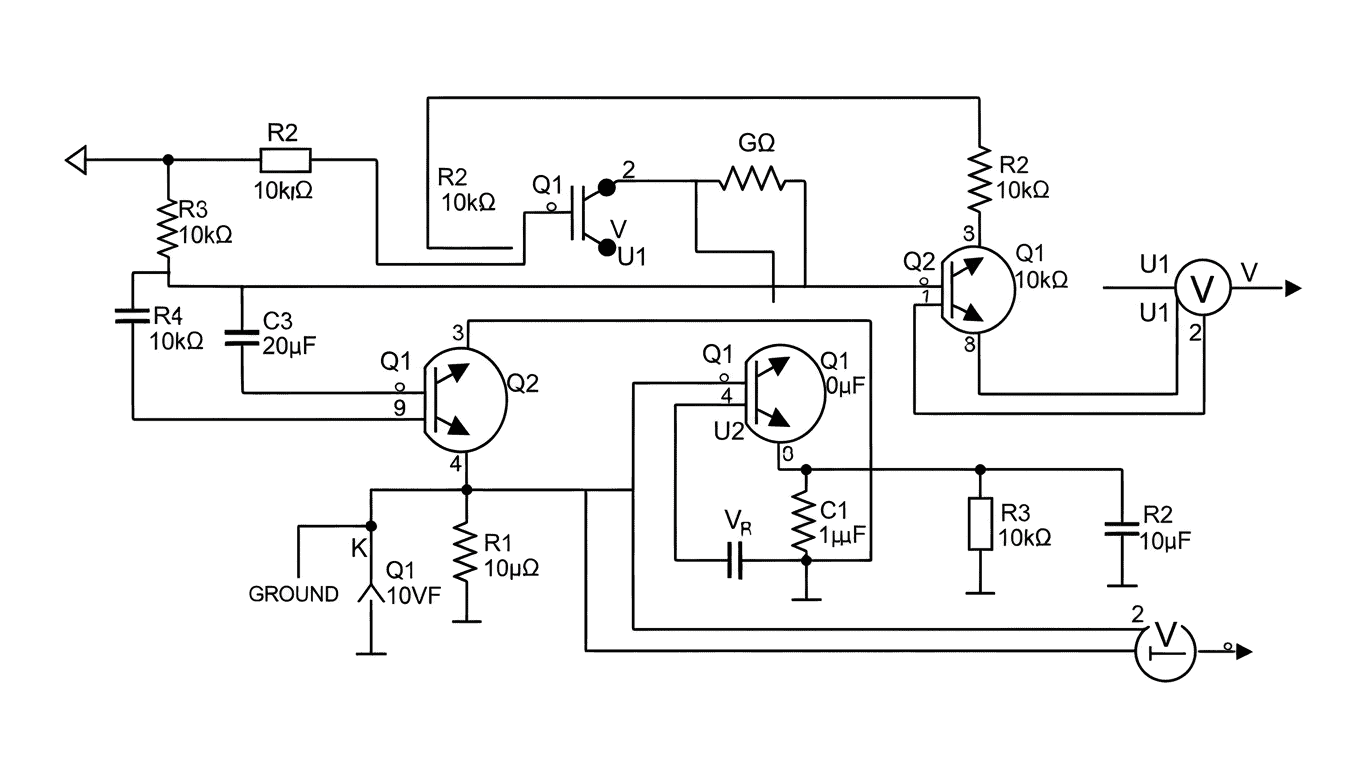

An Alternator Into Generator Wiring Diagram is a schematic that illustrates the necessary electrical connections to convert a vehicle's alternator, designed to charge a battery while the engine runs, into a self-sufficient generator capable of producing usable AC power. In a car, the alternator's primary role is to maintain the battery's charge and power the vehicle's electrical systems. When adapting it for generator use, the goal is to harness its AC output and rectify it into a stable, usable voltage. The importance of a clear and accurate Alternator Into Generator Wiring Diagram cannot be overstated, as incorrect wiring can lead to damage to the alternator, connected devices, or even pose safety hazards.

The typical automotive alternator has several key components that the wiring diagram will address:

- The stator windings (which produce AC voltage)

- The rotor (which is an electromagnet powered by a small DC current, often called the field winding)

- The rectifier (which converts AC to DC)

- The voltage regulator (which controls the output voltage)

When used as a generator, the core challenge is to bypass or adapt the existing voltage regulator and provide a consistent power source for the rotor's field winding. This might involve external components or modifications to the internal circuitry. The diagram will map out these connections, ensuring that the stator's AC output is correctly tapped and, if necessary, rectified to a DC voltage suitable for powering appliances. Here's a simplified look at common connection points:

| Alternator Terminal | Generator Function |

|---|---|

| B+ (Battery Output) | Main AC power output (after rectification) |

| Field/Exciter | Input for DC power to energize the rotor |

| Ground | Common return path |

The actual configuration of an Alternator Into Generator Wiring Diagram can vary significantly depending on the type of alternator (e.g., internal or external regulator) and the desired output. Some diagrams might focus on rectifying the alternator's internal DC output for charging batteries or powering DC devices. Others will aim to extract the raw AC from the stator and then use external components like bridge rectifiers and capacitors to produce AC power suitable for household appliances. A comprehensive diagram will often include:

- Identification of all alternator terminals and their functions.

- The required external components, such as rectifier diodes, voltage regulators, and capacitors.

- The correct polarity and gauge of wiring to be used.

- Connections for an external DC power source to excite the rotor if the original excitation circuit is bypassed.

- Safety features like fuses or circuit breakers.

For anyone embarking on this project, referring to a well-annotated Alternator Into Generator Wiring Diagram is the most reliable way to ensure a successful and safe conversion. The detailed steps and component placements shown in such diagrams are invaluable for hobbyists and DIY enthusiasts. You can find excellent examples and detailed explanations within the resources following this article.