Understanding the inner workings of your welding equipment is crucial for both efficient operation and safety. A key component in many portable welding setups is the alternator, and deciphering its role requires a clear grasp of the Alternator Welder Wiring Diagram. This diagram serves as the blueprint for how your welding machine draws power and converts it into the arc needed for your projects.

Decoding the Alternator Welder Wiring Diagram

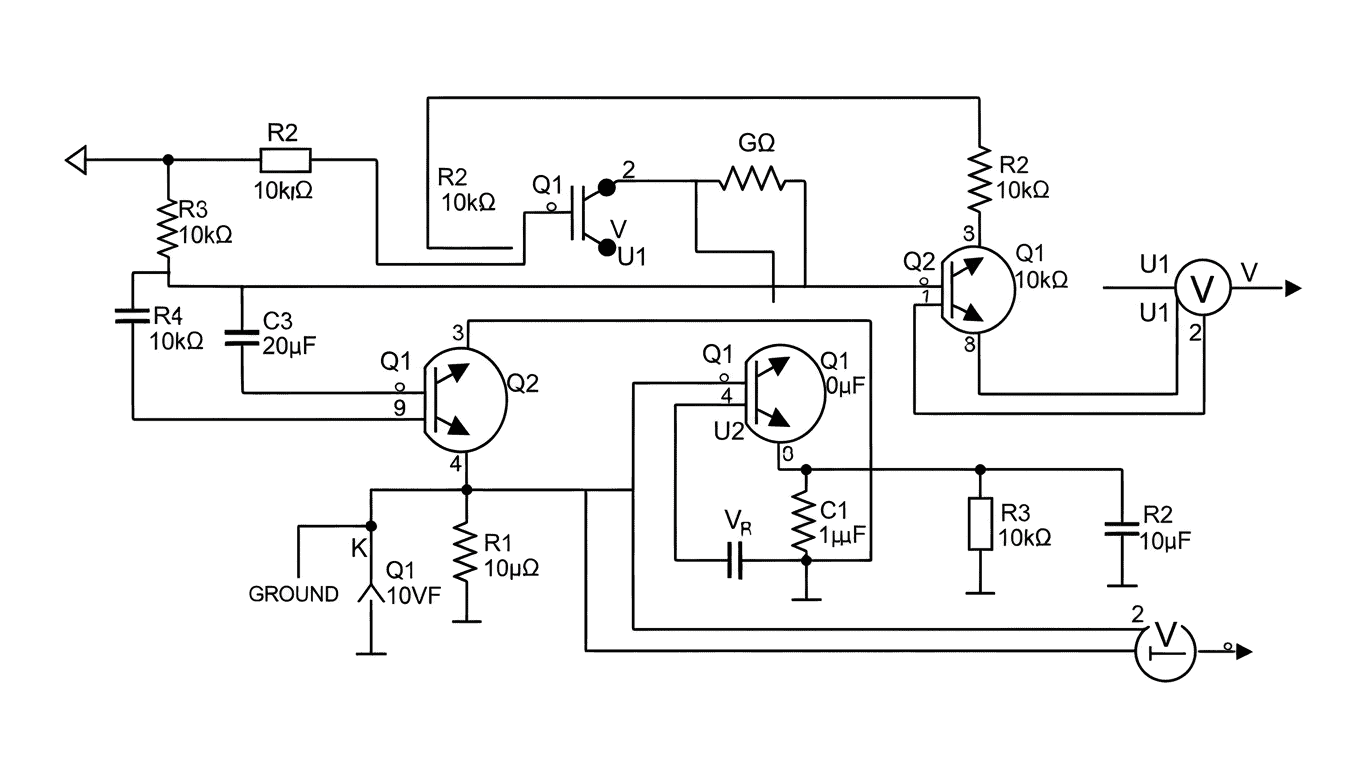

An Alternator Welder Wiring Diagram is essentially a schematic that illustrates the electrical connections within a welding machine that utilizes an alternator as its primary power source. Alternators are sophisticated devices that convert mechanical energy, typically from an engine, into electrical energy. In a welding context, this generated electricity is then further processed to produce the high-amperage, low-voltage direct current (DC) or alternating current (AC) required for welding.

These diagrams are indispensable for several reasons. For starters, they provide a visual roadmap for troubleshooting. When a welder isn't performing as expected, the wiring diagram allows technicians or even DIY enthusiasts to trace the flow of electricity and identify any faulty connections, blown fuses, or malfunctioning components. Moreover, for those looking to build or modify a welder from scratch, the Alternator Welder Wiring Diagram offers the essential instructions for correct assembly. Key elements typically shown include:

- The alternator itself and its output terminals.

- Regulators and rectifiers, which control voltage and convert AC to DC if necessary.

- Capacitors, which store electrical energy.

- Resistors, which control current flow.

- The connection points for the welding leads (electrode holder and ground clamp).

- The input from the engine's charging system (if applicable).

The complexity of an Alternator Welder Wiring Diagram can vary depending on the specific welder model. Simpler units might have a straightforward layout, while more advanced machines with multiple welding modes or sophisticated control systems will feature more intricate diagrams. The importance of correctly interpreting and following these diagrams cannot be overstated, as improper wiring can lead to equipment damage, fire hazards, or even severe electrical shock. It’s vital to consult the diagram provided by the manufacturer for your specific model, as variations exist between different brands and types of alternators used in welding applications. For example, a basic DC welder might look like this in principle:

| Component | Function |

|---|---|

| Engine | Drives the alternator. |

| Alternator | Generates raw AC electricity. |

| Rectifier | Converts AC to DC. |

| Voltage Regulator | Controls the output voltage. |

| Welding Output Terminals | Connects to welding leads. |

Understanding the specific components and their interconnections as laid out in the Alternator Welder Wiring Diagram is the first step towards mastering your welding machine. Whether you're performing routine maintenance or tackling a repair, having this diagram at your fingertips is invaluable.

To gain a deeper understanding and to ensure you are using the most accurate and up-to-date information for your specific welding setup, we highly recommend referring to the detailed Alternator Welder Wiring Diagram provided within your welding machine's official user manual or technical documentation.