Understanding the intricacies of an Accu-coder Encoder Wiring Diagram is crucial for anyone involved in industrial automation, robotics, or any application requiring precise motion control. This diagram serves as the blueprint, detailing how to correctly connect an Accu-coder encoder to your control system, ensuring accurate data transmission and optimal performance. A correctly interpreted Accu-coder Encoder Wiring Diagram is the cornerstone of reliable operation.

Decoding the Accu-coder Encoder Wiring Diagram: The Foundation of Functionality

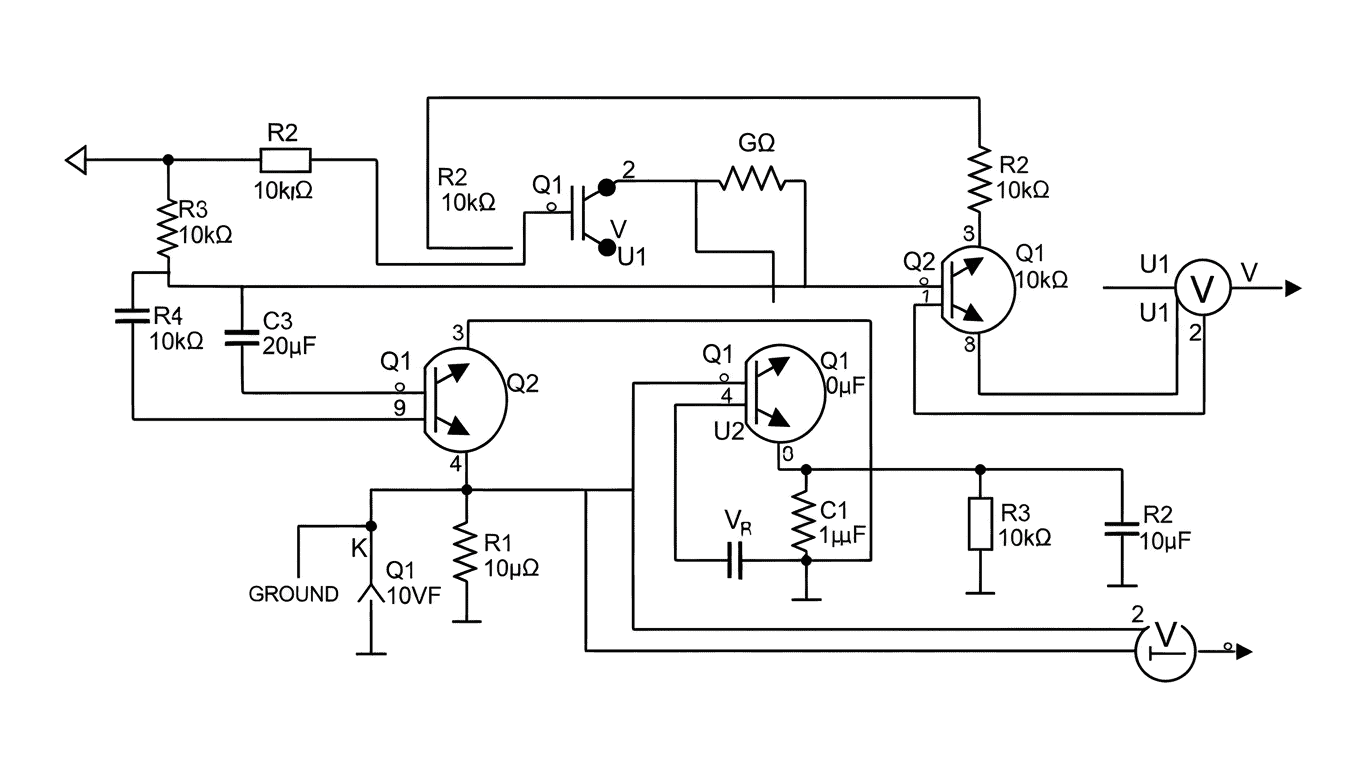

An Accu-coder Encoder Wiring Diagram is essentially a schematic that visually represents the electrical connections between an Accu-coder encoder and the receiving device, such as a programmable logic controller (PLC), servo drive, or microcontroller. These diagrams are indispensable for installation, troubleshooting, and maintenance. They outline which wires correspond to specific functions like power supply, ground, signal outputs (e.g., A, B, Z phases for incremental encoders, or data lines for absolute encoders), and potentially alarm or diagnostic lines. The importance of meticulously following the Accu-coder Encoder Wiring Diagram cannot be overstated, as incorrect wiring can lead to sensor damage, inaccurate readings, system malfunction, or even complete operational failure.

Accu-coder encoders are designed with various output types, and the wiring diagram will reflect these differences. For instance:

- Incremental Encoders: Typically have outputs for Phase A, Phase B, and an Index (Z) pulse. The A and B signals are 90 degrees out of phase to indicate direction, while the Z pulse provides a single reference point per revolution.

- Absolute Encoders: Provide a unique digital code for each shaft position. Their wiring diagrams will show connections for power, ground, and multiple data output lines (e.g., parallel, serial - SSI, BiSS).

The diagram will also specify the voltage requirements and current draw of the encoder, guiding the selection of appropriate power supply and wiring gauge. It will clearly label each terminal or connector pin with its corresponding signal name. Consulting the specific Accu-coder Encoder Wiring Diagram for your model is paramount, as variations exist even within the same manufacturer's product line.

Here's a simplified representation of what you might encounter in a basic Accu-coder Encoder Wiring Diagram:

| Encoder Pin/Terminal | Signal Name | Function |

|---|---|---|

| 1 | +Vdc | Positive Power Supply |

| 2 | GND | Ground |

| 3 | A | Encoder Output Channel A |

| 4 | B | Encoder Output Channel B |

| 5 | Z | Encoder Index/Zero Pulse |

To ensure a successful and robust integration of your Accu-coder encoder, refer to the official Accu-coder Encoder Wiring Diagram provided with your specific encoder model. This detailed document will be your most reliable resource.