Understanding the Accuair Elevel Wiring Diagram is crucial for anyone looking to install, troubleshoot, or simply comprehend the intricacies of their advanced air suspension system. This diagram serves as the blueprint for connecting the various components of your Accuair Elevel system, ensuring it functions flawlessly and safely. Whether you're a seasoned installer or a curious enthusiast, a clear grasp of the Accuair Elevel Wiring Diagram is your key to unlocking the full potential of your vehicle's ride height control.

Decoding the Accuair Elevel Wiring Diagram: A Foundational Understanding

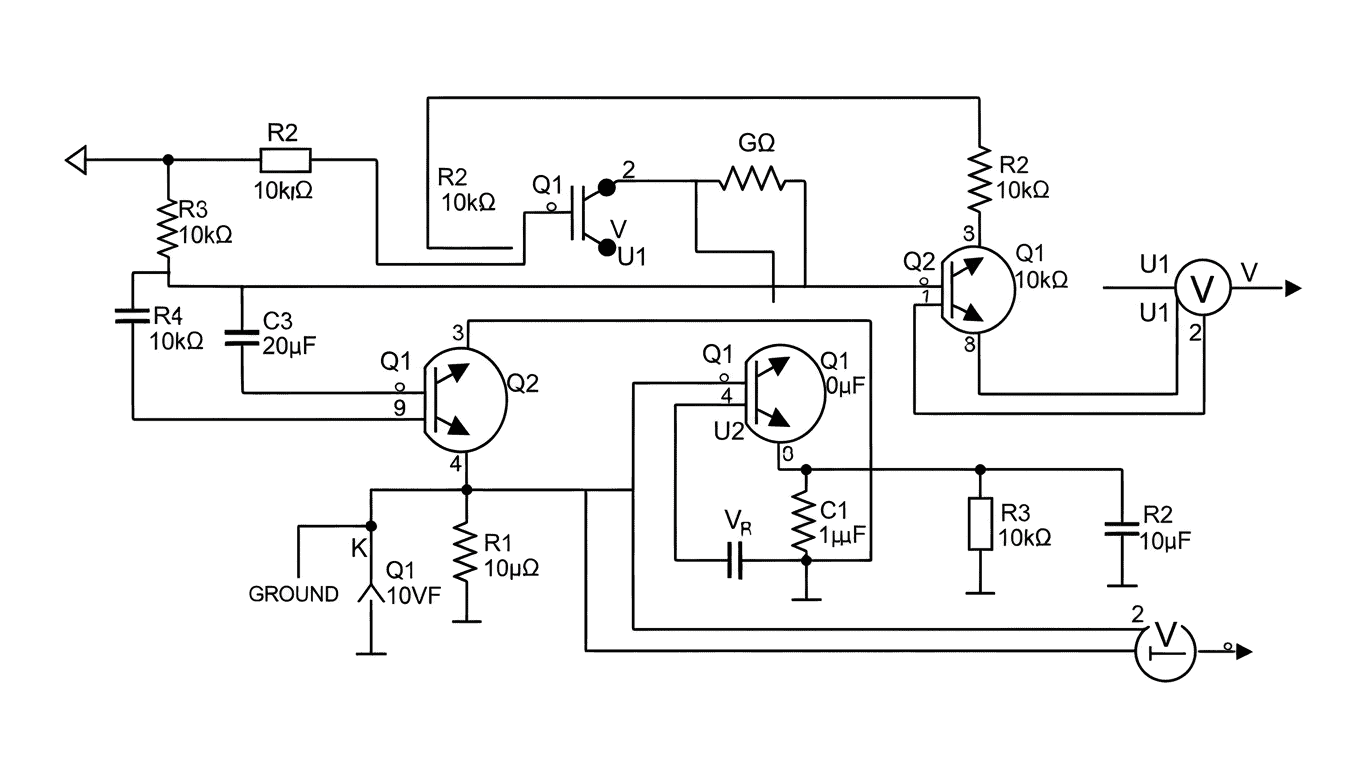

At its core, the Accuair Elevel Wiring Diagram is a visual representation of how electrical signals and power flow between the Elevel control unit, the air compressor, the solenoids, the pressure sensors, and the ride height sensors. It details the specific terminals on each component and the wires that should be connected between them. This detailed layout is essential because air suspension systems involve precise control over air pressure and vehicle height. Incorrect wiring can lead to malfunctioning components, unpredictable ride height, or even damage to the system. The accuracy of your Accuair Elevel Wiring Diagram implementation is paramount for both performance and safety.

The diagram typically outlines the power and ground connections for the Elevel unit itself, ensuring it receives stable electricity to operate. It then maps out the connections to the various output channels that control the solenoid valves. These valves are the gatekeepers of air, allowing it to flow into or out of the air springs to adjust ride height. Additionally, the wiring diagram illustrates how the pressure sensors communicate with the Elevel unit, providing real-time data on the air pressure within the system. This information is vital for the Elevel's intelligent algorithms to maintain desired ride heights and prevent over-pressurization.

Furthermore, the Accuair Elevel Wiring Diagram shows the connections for the ride height sensors. These sensors, often mounted on the suspension components, tell the Elevel unit the current position of each corner of the vehicle. Based on this data, the Elevel system can then command the solenoids to adjust air flow accordingly. A typical setup will involve:

- Power Source: Typically connected directly to the battery with appropriate fusing.

- Ground: A solid connection to the vehicle's chassis is essential.

- Solenoid Outputs: Wires connecting to each solenoid valve (usually one for up, one for down, per corner).

- Pressure Sensor Input: Wires connecting the pressure transducer to the Elevel unit.

- Ride Height Sensor Input: Wires connecting each ride height sensor to the Elevel unit.

For those who are installing a new system or performing extensive modifications, consulting the official Accuair Elevel Wiring Diagram provided by the manufacturer is non-negotiable. It is the definitive guide, ensuring all components are integrated correctly according to the designer's specifications. Without this guide, attempting to wire the system is akin to building a complex machine without instructions – a recipe for frustration and potential failure.

If you're ready to dive deeper into the specifics of your Accuair Elevel setup and ensure a perfect installation or troubleshoot any issues, your best resource is the official documentation. We highly recommend referencing the detailed Accuair Elevel Wiring Diagram provided within your system's installation manual or on the Accuair website. This will provide you with the exact pinouts, wire colors, and connection points specific to your Elevel model.