Understanding your boat's safety systems is paramount, and a Bilge Pump Wiring Diagram With Float Switch is a critical component. This diagram illustrates how your automatic bilge pump is connected, ensuring it activates when water levels rise, protecting your vessel from sinking. It's a straightforward system, but crucial for peace of mind on the water.

Decoding the Bilge Pump Wiring Diagram With Float Switch

A bilge pump wiring diagram with a float switch is essentially a roadmap for how your automatic bilge pump system operates. At its core, a bilge pump is designed to remove unwanted water that accumulates in the lowest part of your boat's hull, known as the bilge. This water can come from various sources, including rain, leaks, or spray. The float switch is the "brain" of the automatic system. It's a device that detects the water level and, when it reaches a predetermined point, it closes an electrical circuit, sending power to the bilge pump to activate it. The importance of a correctly wired and functioning bilge pump with a float switch cannot be overstated; it's a primary safety feature that can save your boat.

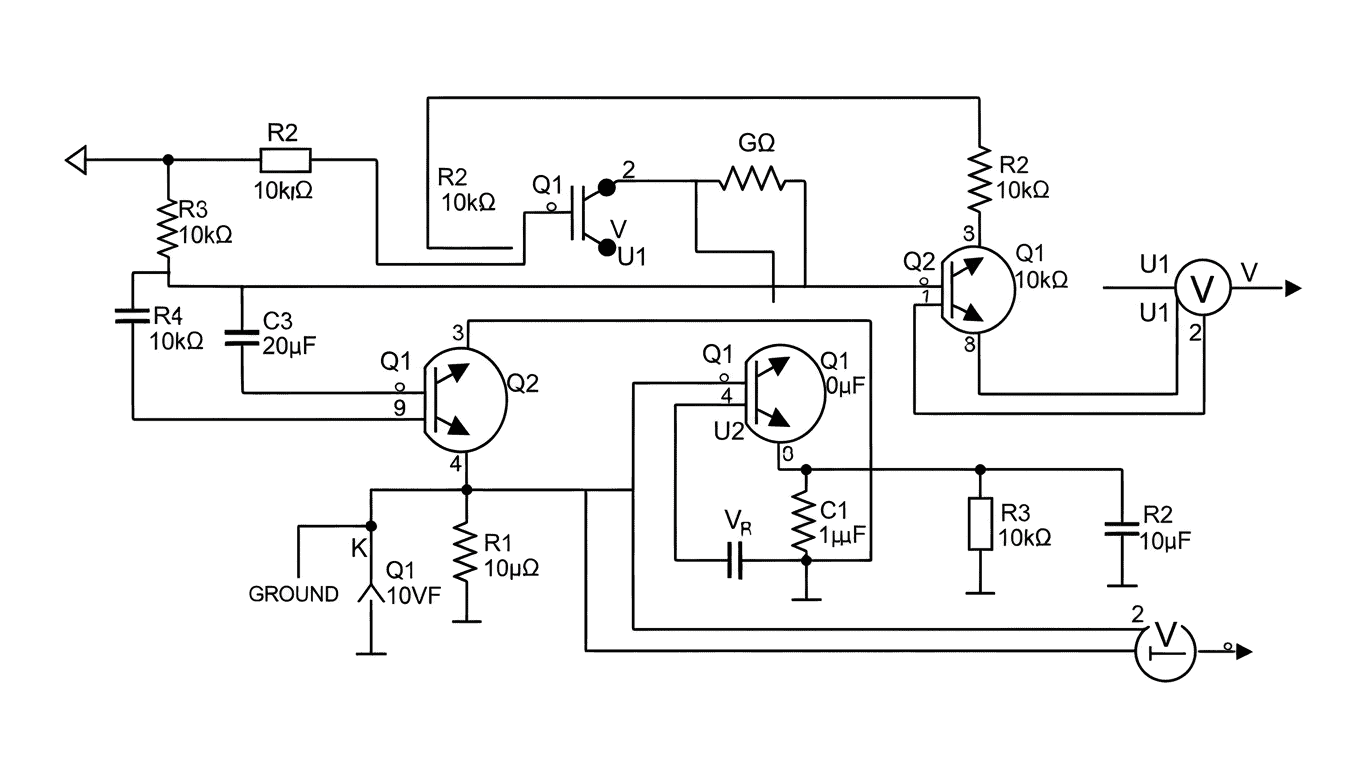

The diagram breaks down the electrical connections necessary for this system to work. Typically, you'll see the following components represented:

- The Bilge Pump: This is the actual pump that expels the water.

- The Float Switch: The water-level sensor.

- The Battery: The power source for the pump.

- In-line Fuse: A safety device to protect the circuit from overcurrent.

- Wire Connections: Illustrating how each component is linked.

Understanding these connections allows for proper installation, troubleshooting, and maintenance. For example, a basic manual override might be included, allowing you to turn the pump on or off manually, independent of the float switch. A common wiring setup involves connecting the positive terminal of the battery through a fuse to the float switch. The float switch then connects to the positive terminal of the bilge pump. The negative terminals of both the float switch and the bilge pump are then connected directly to the negative terminal of the battery. This creates a direct path for power to flow when the float switch is activated.

To illustrate the flow of electricity, consider this simplified representation:

| Battery (+) | --> Fuse --> | Float Switch (Input) |

| Float Switch (Output) | --> Bilge Pump (+) | --> Battery (-) |

| Bilge Pump (-) | (Direct connection to Battery) |

This simple arrangement ensures that as water rises and lifts the float switch, the circuit is completed, and the pump springs into action. Conversely, as the water level drops, the float switch disengages, cutting power to the pump and conserving battery life. Many boats also have a secondary, manual-only pump for redundancy. In more complex systems, you might also find indicators or alarms integrated into the wiring, providing visual or audible alerts when the pump is running or if a problem is detected.

If you need to see precisely how these components are connected for your specific boat, refer to the detailed diagram provided in the next section.