Understanding the Air Compressor Wiring Diagram 230v 1 Phase is crucial for anyone who owns or works with air compressors. This diagram serves as a blueprint, detailing how electrical components are interconnected to power your compressor safely and efficiently. Whether you're performing maintenance, troubleshooting a problem, or installing a new unit, a clear grasp of the Air Compressor Wiring Diagram 230v 1 Phase is essential.

What is an Air Compressor Wiring Diagram 230v 1 Phase and How Are They Used?

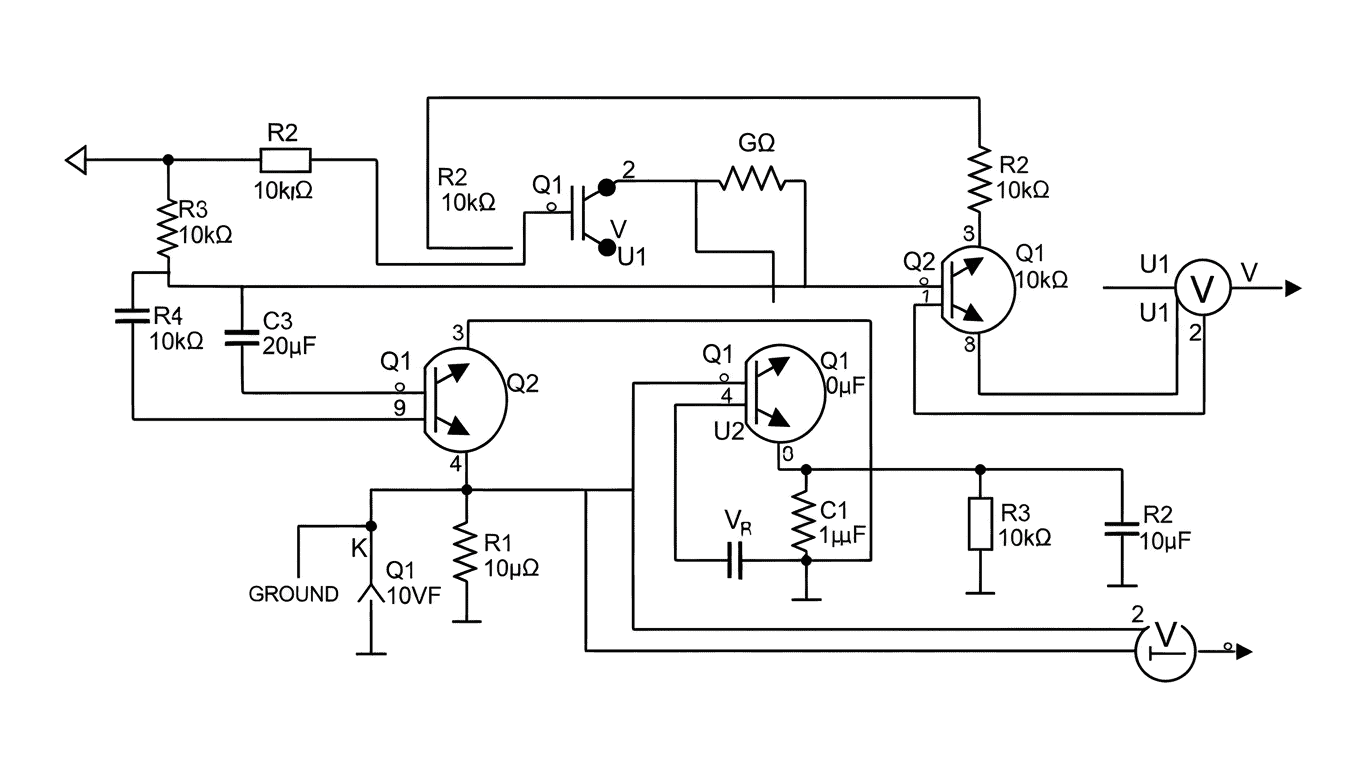

An Air Compressor Wiring Diagram 230v 1 Phase is essentially a visual representation of the electrical connections within a single-phase, 230-volt air compressor system. It outlines the path electricity takes from the power source to the motor, switch, and any other electrical accessories. These diagrams are indispensable tools for electricians, technicians, and even informed DIY enthusiasts. They allow for systematic identification of components, understanding of operational logic, and accurate troubleshooting.

The primary purpose of an Air Compressor Wiring Diagram 230v 1 Phase is to ensure that the compressor receives the correct voltage and current for optimal performance and, more importantly, for safety. Without a proper diagram, attempting to connect or repair a compressor could lead to electrical shocks, component damage, or even fire hazards. Key components typically shown in such a diagram include:

- Power Input (L1, L2 for 230v single phase)

- Motor (Comprising windings, capacitor, and sometimes a starting relay)

- Pressure Switch (Controls motor operation based on tank pressure)

- Thermal Overload Protector (Safety device to prevent motor overheating)

- On/Off Switch or Toggle Switch

- Indicator Lights (Power on, fault indicators)

Understanding the flow of electricity as depicted in the Air Compressor Wiring Diagram 230v 1 Phase enables efficient problem-solving. For instance, if a compressor isn't starting, the diagram helps to trace the electrical path to identify potential breaks or faulty components. This can involve checking the continuity of wires, the functionality of the pressure switch, or the integrity of the motor's capacitor. A well-understood diagram is the foundation for any successful repair or installation. The importance of adhering to the specifications and connections outlined in the Air Compressor Wiring Diagram 230v 1 Phase cannot be overstated for safe and reliable operation.

Here's a simplified breakdown of the typical flow shown in a diagram:

| Stage | Action |

|---|---|

| 1. Power Input | 230 volts enter the system through the power cord. |

| 2. Control Circuit | Electricity passes through the on/off switch and then to the pressure switch. |

| 3. Motor Activation | When pressure is low, the pressure switch closes, allowing power to reach the motor. |

| 4. Motor Operation | The motor starts, driving the compressor pump. |

| 5. Pressure Cut-off | When the tank reaches the preset pressure, the pressure switch opens, cutting power to the motor. |

| 6. Safety Monitoring | The thermal overload protector continuously monitors motor temperature. |

To ensure you have the most accurate and relevant information for your specific air compressor model, please refer to the detailed diagrams provided in the sections that follow.