Navigating the world of ignition systems can be complex, especially when it comes to understanding the nuances of different CDI (Capacitor Discharge Ignition) units. A crucial aspect of this understanding lies in deciphering the AC Vs DC CDI Wiring Diagram. This article will break down what these diagrams represent, why they are different, and how their unique characteristics influence their use in various applications.

Understanding the AC Vs DC CDI Wiring Diagram

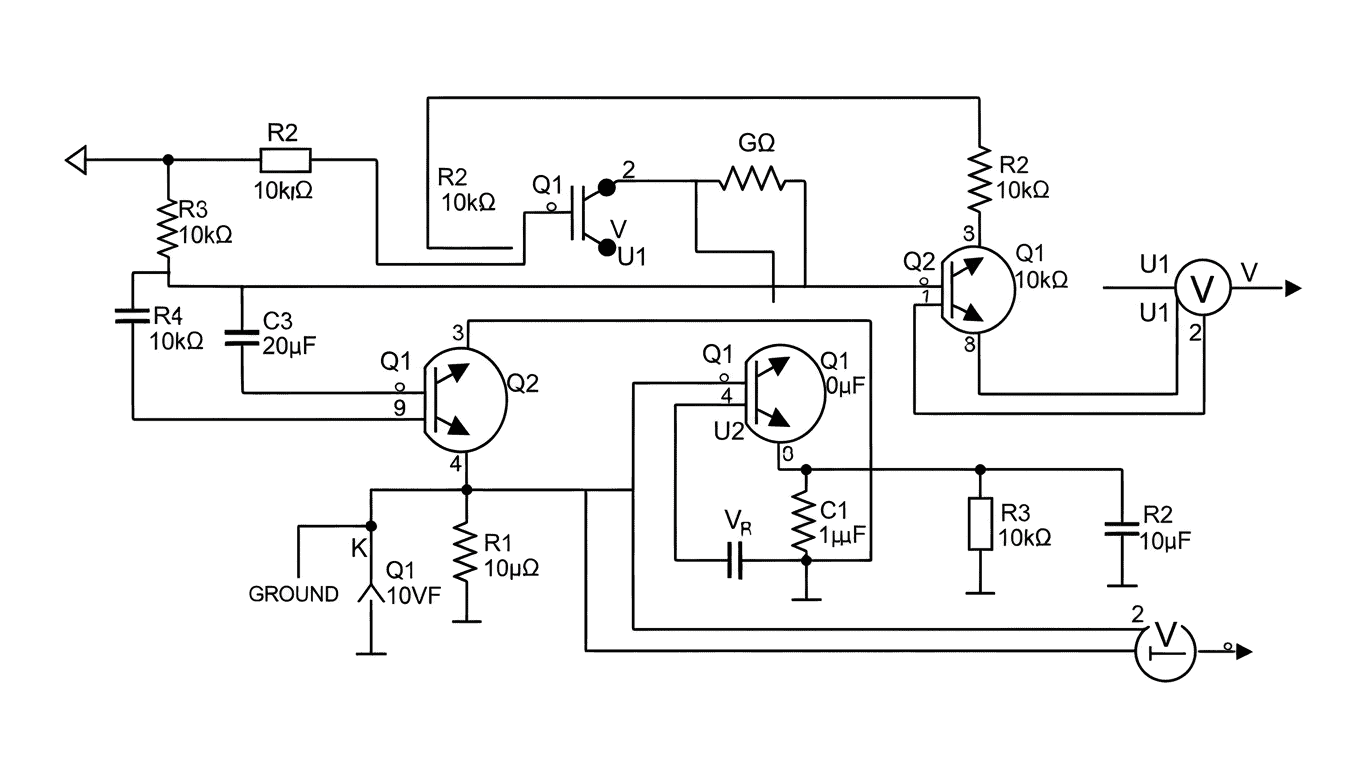

At its core, a CDI system is designed to store electrical energy and then rapidly discharge it to the ignition coil, generating a powerful spark for combustion. The fundamental difference between AC and DC CDI units, and therefore their wiring diagrams, lies in the source of this stored energy. An AC CDI unit typically draws its power directly from the alternator or a similar AC source within the vehicle's electrical system. This means the CDI unit itself needs to rectify this AC power into DC to charge its internal capacitor. A DC CDI unit, on the other hand, receives its power from a DC source, usually the vehicle's battery, often through a voltage regulator to ensure a stable input. The correct understanding and implementation of the AC Vs DC CDI Wiring Diagram are paramount for ensuring proper ignition timing, reliable engine performance, and preventing damage to the electrical components.

The wiring for each type reflects these power source differences. For an AC CDI, you'll often find connections for:

- Pick-up coil signal (trigger)

- Ground

- To ignition coil

- Power from AC source (stator/alternator)

In contrast, a DC CDI typically includes connections for:

- Battery positive (12V DC)

- Battery negative (ground)

- Pick-up coil signal (trigger)

- To ignition coil

Here's a simplified comparison:

| Feature | AC CDI | DC CDI |

|---|---|---|

| Power Source | Alternator/Stator (AC) | Battery (DC) |

| Complexity | Internal rectification required | Simpler, direct DC input |

The operational characteristics also vary. AC CDI units tend to be simpler and more robust, often found in older or simpler engine designs like many motorcycles and scooters. They might have a less consistent spark at very low RPMs because their charging rate is tied to engine speed. DC CDI units, powered by the battery, generally provide a more consistent and powerful spark across a wider range of RPMs, making them suitable for performance applications and more modern vehicles where precise ignition control is beneficial.

To truly grasp the intricacies of these systems and ensure you're making the right connections for your specific application, it's highly recommended to consult the detailed information available in the technical manuals and guides provided with your AC or DC CDI unit.