Understanding an Ac Motor Start Capacitor Wiring Diagram is crucial for anyone looking to repair, maintain, or even just understand how many common household appliances and industrial equipment work. This diagram acts as a blueprint, detailing the specific connections required to ensure an AC motor starts efficiently and reliably. Let's dive into what makes these diagrams so important.

The Role and Purpose of an Ac Motor Start Capacitor Wiring Diagram

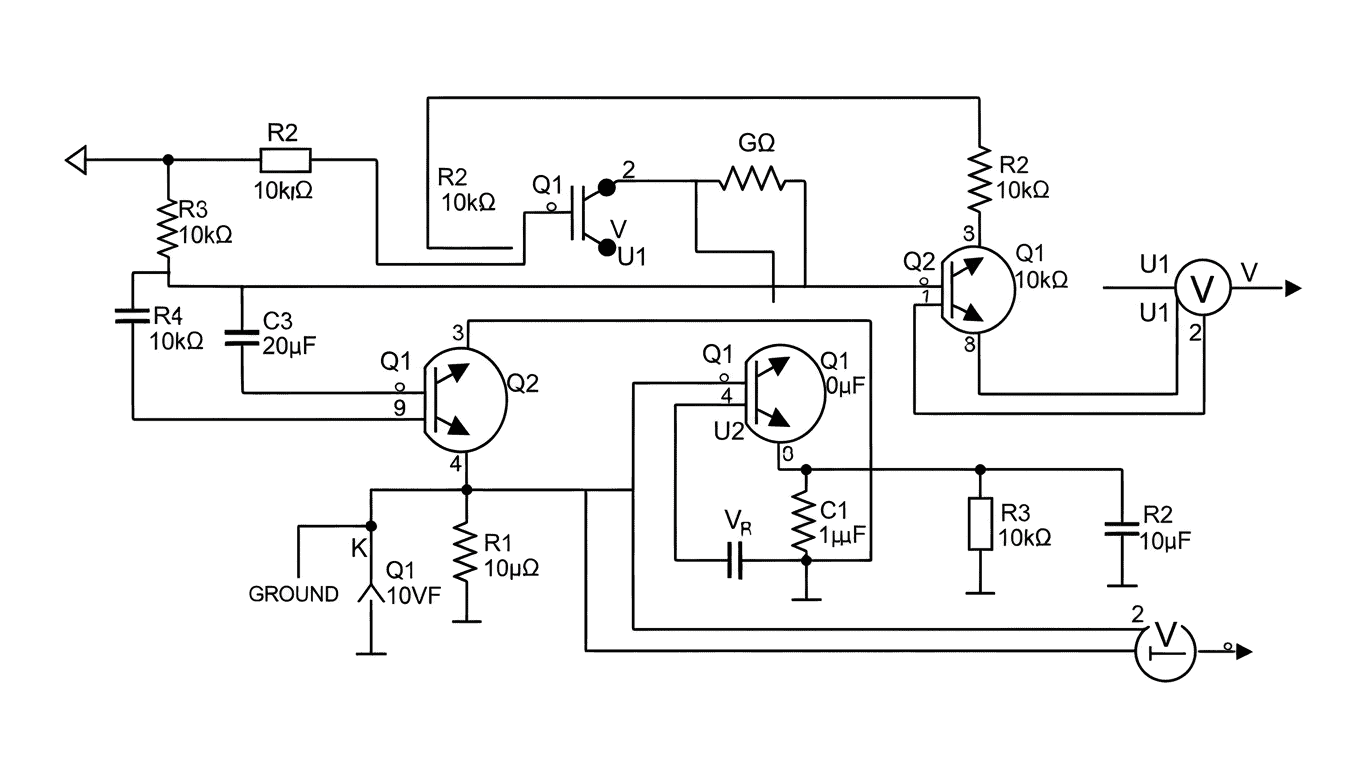

An AC motor start capacitor wiring diagram illustrates how a start capacitor is integrated into the electrical circuit of a single-phase AC induction motor. Unlike three-phase motors which naturally generate a rotating magnetic field, single-phase motors need an extra push to get going. This is where the start capacitor comes in. It provides a phase shift to the current in the auxiliary winding, creating a temporary rotating magnetic field that gives the motor the initial torque it needs to start turning.

The process involves the capacitor being connected in series with the motor's starting (or auxiliary) winding. This circuit is energized only during the start-up phase. Once the motor reaches a certain speed (typically around 75-80% of its rated speed), a centrifugal switch or a potential relay disconnects the start capacitor from the circuit. This is essential because if the capacitor remained connected, it could overheat and be damaged, and it would also reduce the motor's efficiency and power output during normal operation.

The importance of a correct Ac Motor Start Capacitor Wiring Diagram cannot be overstated. Incorrect wiring can lead to several problems:

- The motor may not start at all.

- The motor may hum but not turn.

- The motor may start slowly or with insufficient torque.

- Overheating and premature failure of the capacitor or motor.

Here's a simplified look at the key components involved in a typical diagram:

| Component | Function |

|---|---|

| Main Winding | Carries the primary current for motor operation. |

| Auxiliary (Start) Winding | Provides the initial phase shift for starting. |

| Start Capacitor | Stores and releases electrical energy to create the phase shift. |

| Centrifugal Switch/Potential Relay | Disconnects the start capacitor once the motor is up to speed. |

Understanding these relationships, as depicted in the diagram, is fundamental to troubleshooting and successful repair.

To see a practical example and get a clearer picture of how these connections are made, we highly recommend referring to the detailed diagrams available in the next section.