Understanding the "Absolute Encoder Wiring Diagram" is crucial for anyone integrating these sophisticated sensors into their automation and control systems. An Absolute Encoder Wiring Diagram serves as the blueprint, detailing how to correctly connect the encoder to your control system, ensuring accurate and reliable position feedback. Without a proper wiring diagram, achieving the precision these devices offer can be challenging, leading to potential errors and system malfunctions. This guide will illuminate the essential aspects of an Absolute Encoder Wiring Diagram.

Decoding the Absolute Encoder Wiring Diagram

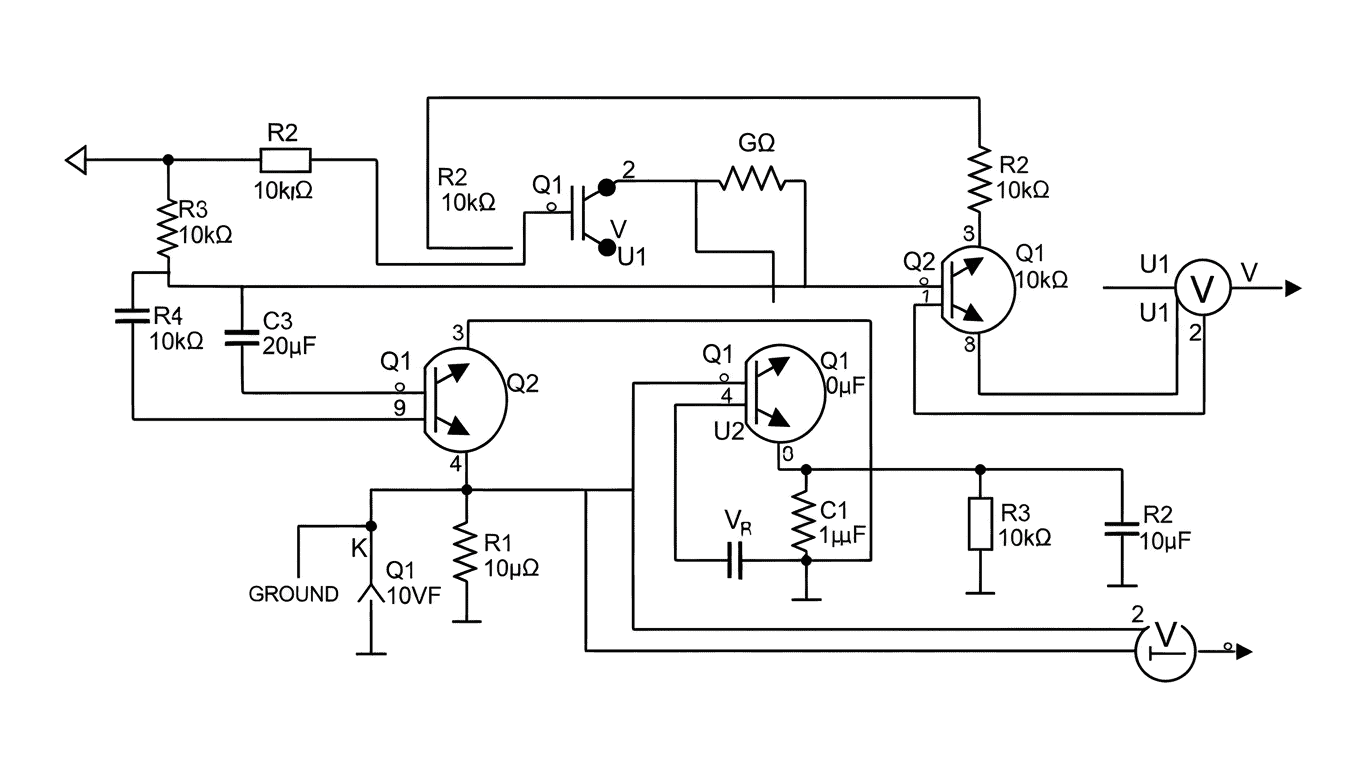

An "Absolute Encoder Wiring Diagram" is more than just a collection of lines and symbols; it's a vital instruction manual for establishing communication between your absolute encoder and its receiving device, typically a Programmable Logic Controller (PLC) or a dedicated motion controller. Unlike incremental encoders that measure relative movement from a home position, absolute encoders provide a unique digital code for every shaft position, meaning they know their exact location even after power loss and re-initialization. This inherent knowledge makes them indispensable in applications where maintaining absolute position is paramount.

The diagram will typically illustrate the power supply connections (DC voltage is common), ground connections, and the data output lines. The specific interface protocol will dictate the number and function of these data lines. Common interfaces include:

- Parallel: Offers high data transfer rates but requires more wiring.

- Serial (e.g., SSI, BiSS): More efficient in terms of wiring, often used for higher resolutions.

- Fieldbus (e.g., Profibus, EtherNet/IP): Integrates directly into industrial networks for seamless data exchange.

The importance of adhering strictly to the "Absolute Encoder Wiring Diagram" cannot be overstated. Incorrect wiring can lead to:

- Data corruption or loss.

- Damage to the encoder or the control system.

- Inaccurate position readings.

- System downtime.

Here's a simplified example of common connections you might find in an "Absolute Encoder Wiring Diagram":

| Encoder Pin | Function | Example Connection |

|---|---|---|

| V+ / DC Power | Encoder power supply positive terminal | PLC +24VDC |

| GND / 0V | Encoder power supply ground | PLC 0V |

| DATA 0, DATA 1... | Digital position data output | PLC Digital Input (specific pins) |

| CLOCK / DATA VALID | Timing or signal for data transfer | PLC Digital Input (specific pins) |

Consulting the specific "Absolute Encoder Wiring Diagram" provided by the encoder manufacturer for your model is the most reliable way to ensure a successful installation. These diagrams are tailored to the encoder's unique specifications and interface. For detailed insights and specific connection examples, please refer to the documentation provided with your absolute encoder. This will be your definitive guide to a correct and efficient setup.