Understanding the Abb Vfd Control Wiring Diagram is fundamental for anyone looking to effectively implement and manage variable frequency drives (VFDs) in their industrial or commercial applications. This diagram serves as the blueprint for connecting the control signals to the VFD, enabling precise management of motor speed, torque, and other operational parameters. Whether you're a seasoned technician or new to VFD technology, a clear grasp of the Abb Vfd Control Wiring Diagram ensures safe, reliable, and optimized performance.

Decoding the Abb Vfd Control Wiring Diagram

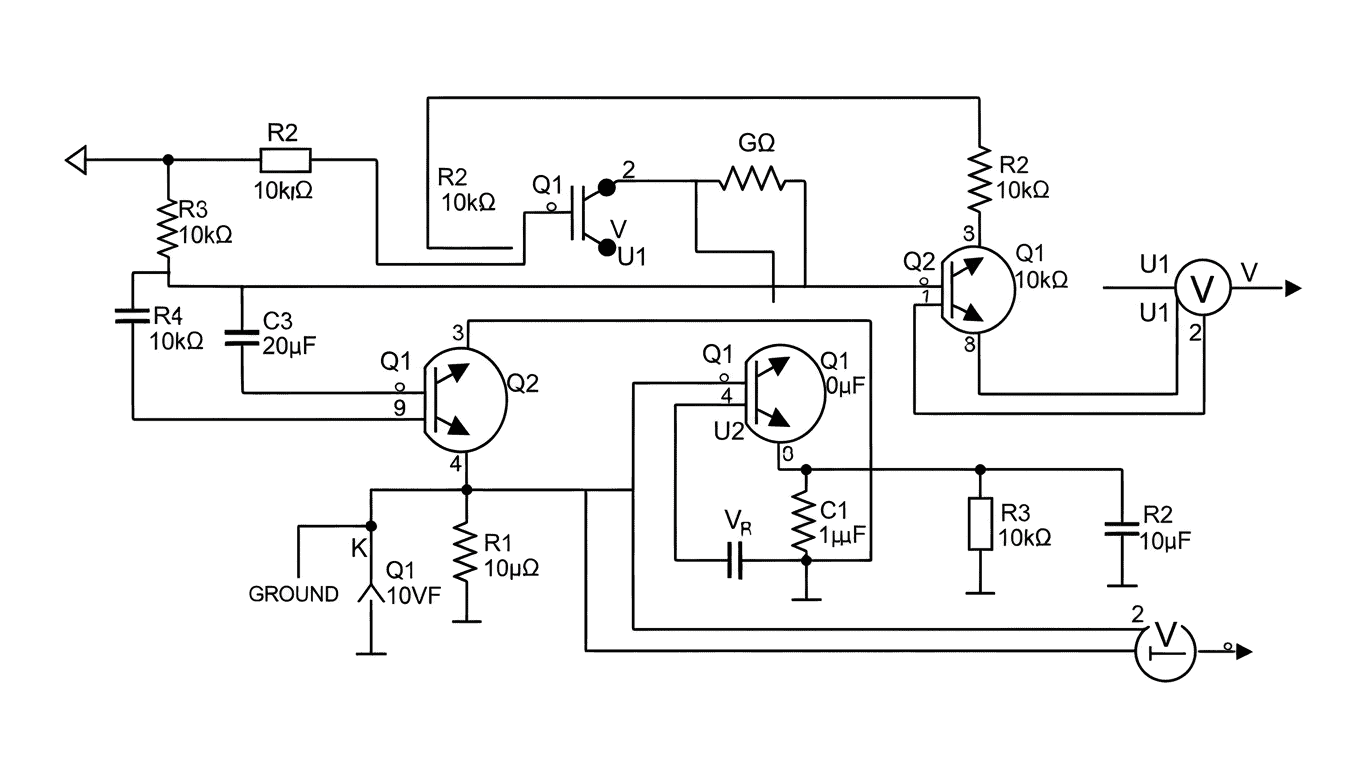

An Abb Vfd Control Wiring Diagram is essentially a schematic illustration that details how to connect the various control inputs and outputs of an ABB Variable Frequency Drive. These diagrams are crucial because they guide the electrical connections for features like starting and stopping the motor, setting speed references, monitoring status, and integrating with other control systems. Without the correct wiring based on the Abb Vfd Control Wiring Diagram, the VFD cannot function as intended, potentially leading to inefficient operation, system malfunctions, or even damage to equipment.

The primary purpose of the Abb Vfd Control Wiring Diagram is to facilitate a connection between the VFD's control terminals and external devices. These devices can include simple pushbuttons, limit switches, analog sensors (like potentiometers or pressure transmitters), and communication modules. The diagram clearly labels each terminal on the VFD and specifies the type of signal that should be connected. For instance, it will show where to connect digital inputs for start/stop commands, analog inputs for speed setpoints, and outputs for relaying status information like "running" or "fault." The ability to precisely control these aspects is vital for energy savings and process optimization .

Here's a breakdown of what you'll typically find in an Abb Vfd Control Wiring Diagram:

- Digital Inputs (DI): For ON/OFF signals, such as start, stop, forward, reverse, or fault reset.

- Analog Inputs (AI): To receive variable signals for speed reference (e.g., 0-10V or 4-20mA), torque control, or process feedback.

- Relay Outputs (RO): To signal the status of the VFD to other control systems, like indicating that the motor is running, has a fault, or is at a certain speed.

- Digital Outputs (DO): For discrete ON/OFF status signals.

- Communication Ports: For connecting to industrial networks (e.g., Modbus, Profibus) for advanced control and monitoring.

The diagram also illustrates power connections for the control circuits, ensuring that the VFD receives the necessary low-voltage power to operate its internal logic and receive external control signals. Following these instructions meticulously is paramount for safe and effective VFD integration.

To ensure you're working with the most accurate and relevant information for your specific ABB VFD model, always refer to the official documentation provided with your unit. The detailed schematics and component listings within these manuals are indispensable for correct installation and troubleshooting.