Navigating the intricacies of industrial automation can often feel like deciphering a complex puzzle. At the heart of many modern industrial processes lies the Variable Speed Drive (VSD), and understanding its control wiring is paramount. This article will delve into the world of the Abb Drive Control Wiring Diagram, offering a clear and comprehensive explanation of its significance and application.

What is an Abb Drive Control Wiring Diagram and Why is it Crucial?

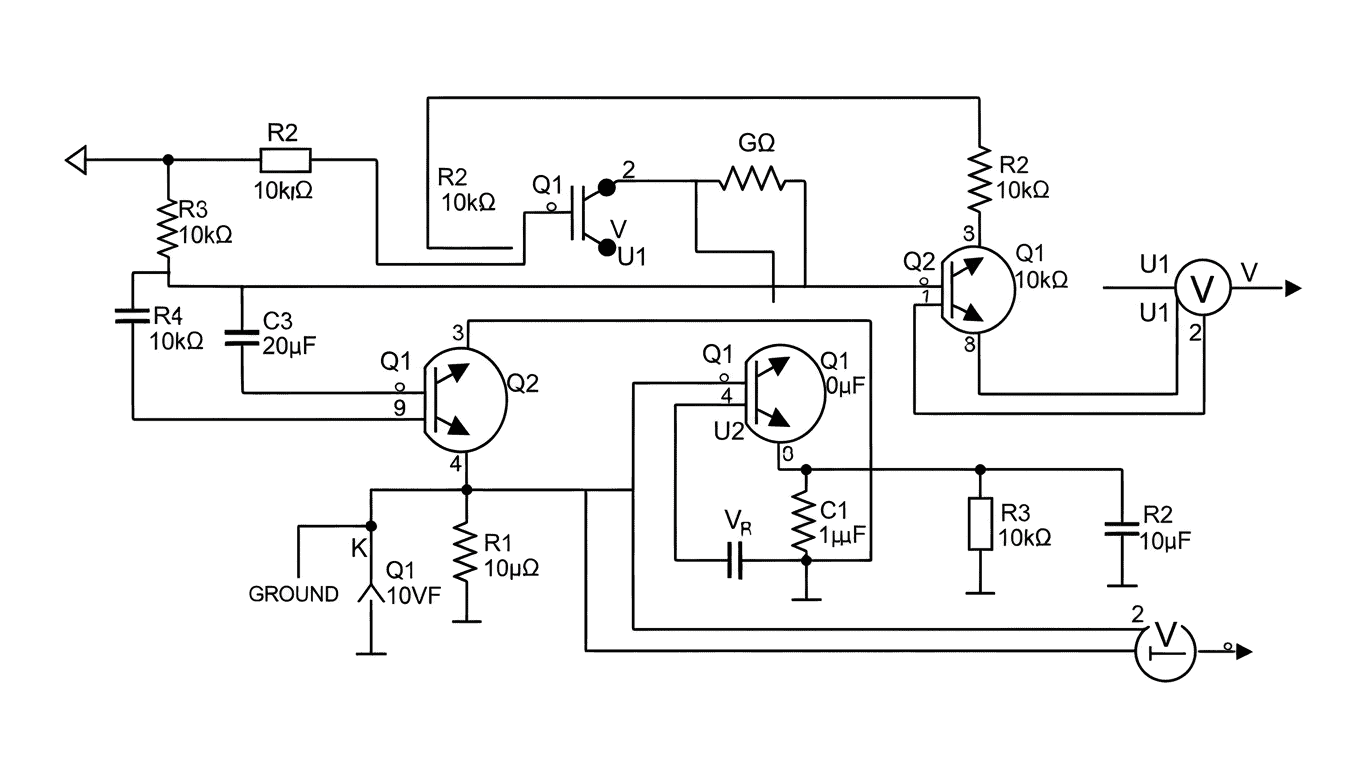

An Abb Drive Control Wiring Diagram is essentially a blueprint that illustrates how to connect the various control components to an ABB variable speed drive. These diagrams are meticulously designed to show the electrical pathways for signals that dictate the drive's operation. They detail connections for inputs such as start/stop commands, speed reference signals, and fault resets, as well as outputs that can signal the drive's status, such as running, fault, or at speed. Think of it as the nervous system of your motor control system, directing the "brain" (the drive) on how to perform its tasks.

The importance of a correct Abb Drive Control Wiring Diagram cannot be overstated. Proper wiring ensures the safe, efficient, and reliable operation of the motor and the entire system. Incorrect connections can lead to malfunctioning equipment, potential damage, and even safety hazards. The diagrams serve multiple purposes:

- Installation Guidance: They provide step-by-step instructions for electricians and technicians.

- Troubleshooting: When issues arise, the diagram is the first point of reference for diagnosing problems.

- Modification and Expansion: They help in understanding how to integrate the drive into existing systems or expand its functionality.

Understanding the symbols and conventions used in these diagrams is key. For instance, you'll typically find representations for:

| Symbol | Component |

|---|---|

| Lines | Electrical Connections |

| Rectangles | Terminal Blocks |

| Circles | Input/Output Terminals |

A typical wiring scenario might involve connecting a simple push button to a digital input terminal for start/stop control. For more advanced applications, the diagram will illustrate connections for analog signals (e.g., a 0-10V or 4-20mA signal from a sensor to set speed), communication protocols (like Modbus or Profibus), and safety interlocks. The level of detail in an Abb Drive Control Wiring Diagram ensures that even complex control strategies can be implemented accurately.

To truly grasp the practical application of an Abb Drive Control Wiring Diagram, it's highly recommended to refer to the specific documentation provided by ABB for the drive model you are using. This will offer the most accurate and detailed schematics tailored to your equipment.