The A And A Scales Wiring Diagram is a crucial document for anyone involved in the setup, maintenance, or troubleshooting of weighing systems. Understanding this diagram is key to ensuring the accuracy, reliability, and longevity of your scales. Whether you're a technician, a business owner, or simply curious about how these essential tools work, delving into the specifics of the A And A Scales Wiring Diagram will provide invaluable insights.

Understanding Your A And A Scales Wiring Diagram

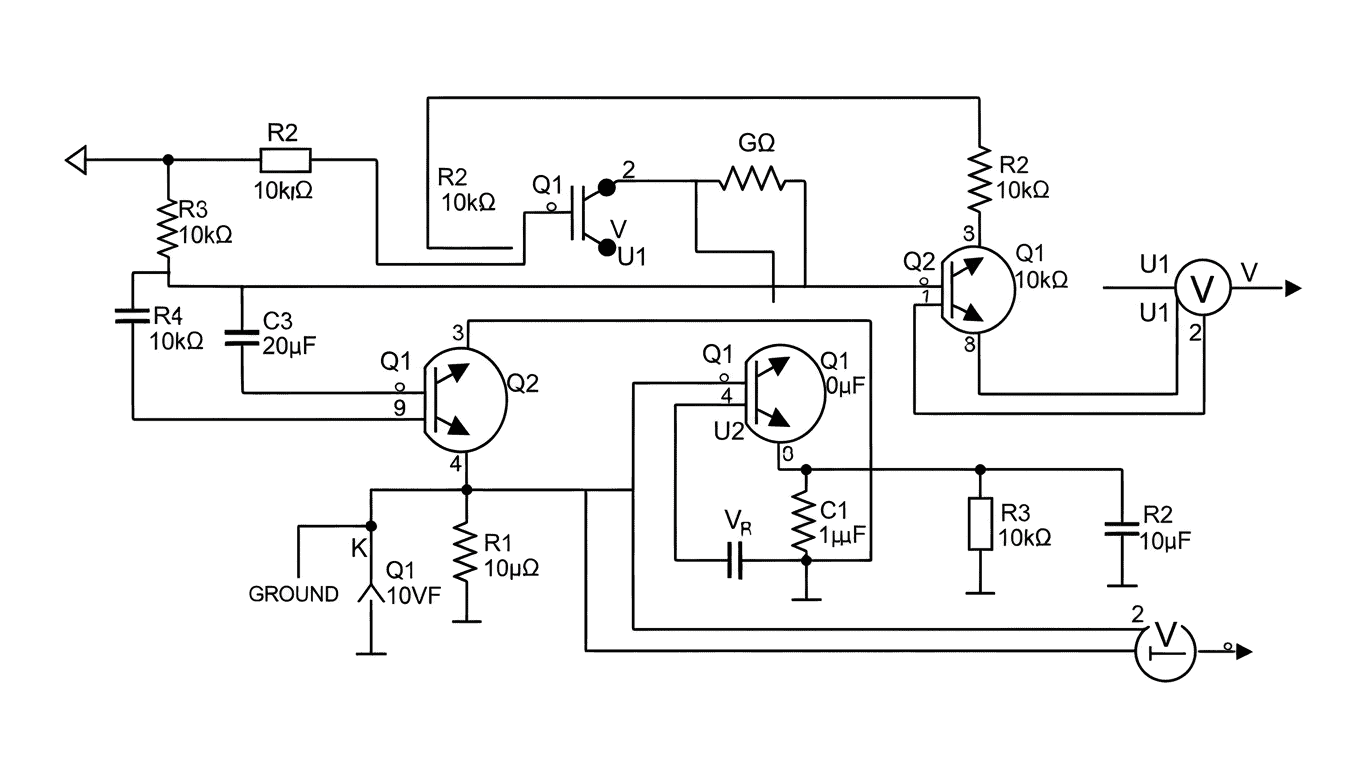

An A And A Scales Wiring Diagram is essentially a blueprint that illustrates the electrical connections within a weighing system. It details how various components, such as load cells, indicators, power supplies, and communication interfaces, are linked together. These diagrams are not just technical drawings; they are vital tools that help in the correct installation of new equipment, assist in diagnosing problems when a scale isn't performing as expected, and guide routine maintenance to keep everything running smoothly.

The complexity of the A And A Scales Wiring Diagram can vary depending on the type of scale. A simple bench scale might have a straightforward diagram, while an industrial weighbridge would feature a much more intricate one. Generally, you'll find standard symbols representing different electrical components. For instance, a resistor might be shown as a zig-zag line, a wire as a solid line, and a power source with a battery symbol. Some diagrams also include color codes for wires, which are immensely helpful in tracing connections. The ability to read and interpret these symbols and connections is fundamental to ensuring the integrity of your weighing operations . Below is a simplified overview of common components you might encounter:

- Load Cells: The sensors that detect weight.

- Indicator/Display: Shows the weight reading.

- Junction Box: Connects multiple load cells to the indicator.

- Power Supply: Provides the necessary electrical power.

- Output Devices: Such as printers or computers for data logging.

The A And A Scales Wiring Diagram plays a critical role in the calibration process. By understanding the connections, technicians can ensure that the signals from the load cells are accurately transmitted to the indicator. Furthermore, during troubleshooting, the diagram acts as a roadmap to pinpoint faulty connections, damaged wires, or improperly functioning components. Without it, identifying the source of an error could be a time-consuming and frustrating guessing game. Here are a few key uses:

- Installation: Guiding the correct hook-up of all electrical parts.

- Troubleshooting: Identifying and resolving electrical faults.

- Maintenance: Planning and executing preventative checks.

- Upgrades: Facilitating the integration of new components.

When dealing with an A And A Scales Wiring Diagram, pay close attention to specifications like voltage, current ratings, and wire gauges. These details are not arbitrary; they are essential for safe and effective operation. For instance, using a wire that is too thin for the required current can lead to overheating and potential fire hazards. Similarly, incorrect voltage can damage sensitive electronic components.

To gain a comprehensive understanding of your specific A And A Scales Wiring Diagram and to ensure your weighing system operates at its peak performance, we highly recommend consulting the official documentation provided with your scale. This will offer the most accurate and detailed information tailored to your equipment.