Navigating the electrical system of your motorcycle, ATV, or scooter can seem daunting, especially when dealing with the ignition system. A crucial component in this system is the CDI (Capacitor Discharge Ignition), and understanding its wiring is paramount for maintenance and repairs. This article will delve into the specifics of an 8 Wire CDI Wiring Diagram, demystifying its components and their functions, so you can get your engine firing on all cylinders once more.

The Ins and Outs of an 8 Wire CDI Wiring Diagram

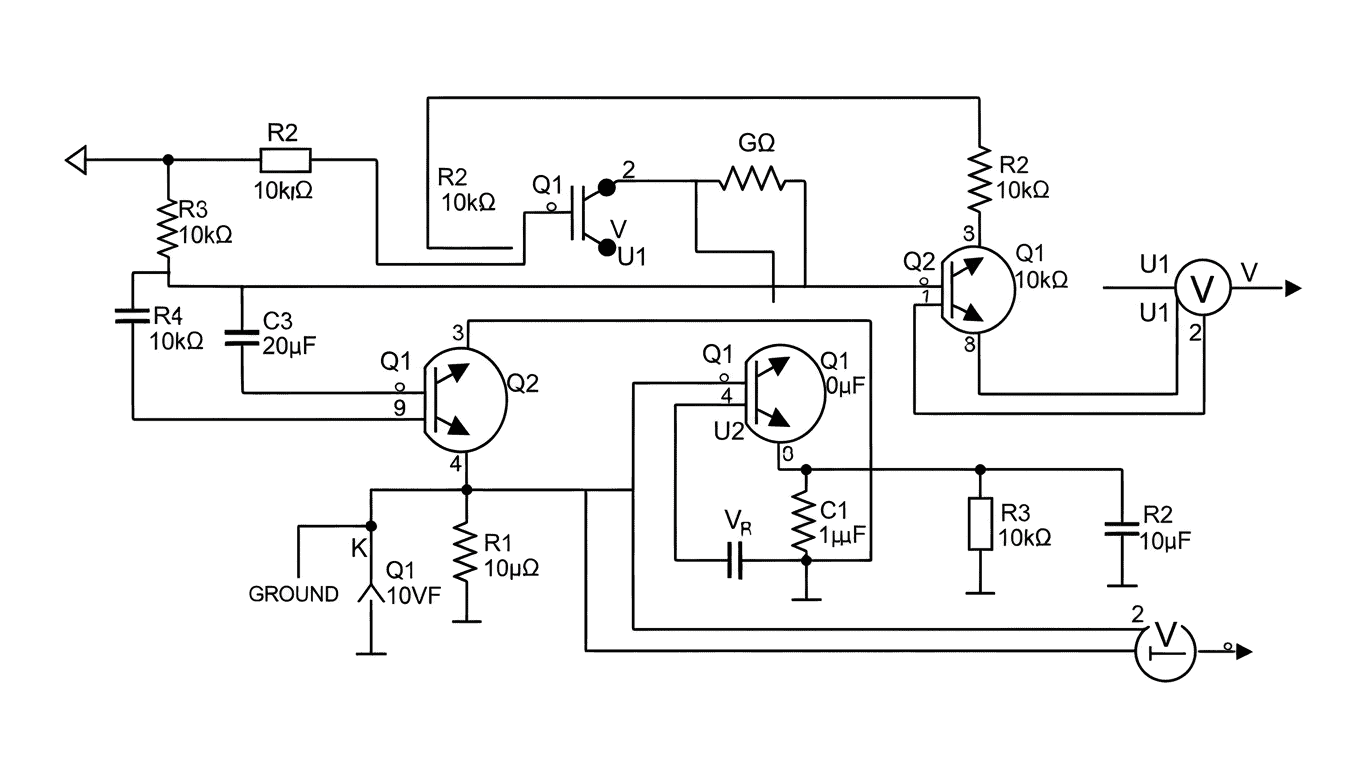

An 8 Wire CDI Wiring Diagram is essentially a roadmap for the electrical signals that control your vehicle's ignition. The CDI unit itself is a small electronic box that stores electrical energy and then discharges it at precisely the right moment to fire the spark plug. The number of wires indicates the complexity of the system it's designed for, typically meaning it manages more features or has more sophisticated control over ignition timing. Understanding this diagram is crucial for proper troubleshooting and ensuring your engine receives the correct spark at the right time.

These diagrams illustrate the connections between the CDI module, the motorcycle's electrical components, and the power source. Each wire has a specific purpose:

- Power Input: Receives power from the battery or stator.

- Ground: Provides a return path for electrical current.

- Trigger/Pulser Coil Input: Receives a signal from the pulser coil to initiate the ignition sequence.

- Kill Switch Input: Allows you to shut off the engine by grounding the CDI.

- Ignition Coil Output: Sends the high-voltage pulse to the ignition coil.

- Timing Advance/Retard (if applicable): Some advanced CDIs have inputs to adjust ignition timing based on engine RPM or other factors.

- Lighting/Accessory Output (less common): In some integrated systems, the CDI might also manage lighting.

- Neutral/Gear Position Sensor Input (if applicable): To prevent starting in gear or to adjust timing based on gear.

When troubleshooting ignition issues, following the 8 Wire CDI Wiring Diagram is your primary tool. You'll systematically check for voltage at the power input, continuity on the ground wire, and proper signal from the pulser coil. The diagram helps you isolate problems, whether it's a faulty CDI unit, a broken wire, or an issue with another component like the ignition coil. Here's a simplified representation of potential wire functions, though your specific diagram may vary:

| Wire Color (Typical) | Function |

|---|---|

| Red | Power Input (+) |

| Black/White | Ground (-) |

| Blue/White | Pulser Coil Signal |

| Black | Kill Switch |

| Yellow/Black | Ignition Coil Output |

| Other Colors | Various sensors, timing inputs, etc. |

A common scenario for an 8-wire CDI involves features like variable ignition timing, which can significantly improve engine performance and fuel efficiency. The diagram will show how sensors feeding information about engine speed (RPM) or throttle position connect to the CDI, influencing the precise moment the spark plug fires. Without a clear understanding of this diagram, diagnosing issues related to these advanced features becomes incredibly difficult.

If you are working on a specific vehicle and need to accurately identify the function of each wire on your 8 Wire CDI Wiring Diagram, we strongly recommend consulting the detailed diagrams available through your vehicle's service manual. This will provide the most precise and accurate information for your particular application.