Understanding the intricacies of an 8 Pin Time Delay Relay Wiring Diagram is crucial for anyone working with automated systems or requiring precise timing in electrical circuits. This article will demystify the common configurations and applications of these versatile components, ensuring you can confidently implement them in your projects.

Decoding the 8 Pin Time Delay Relay Wiring Diagram

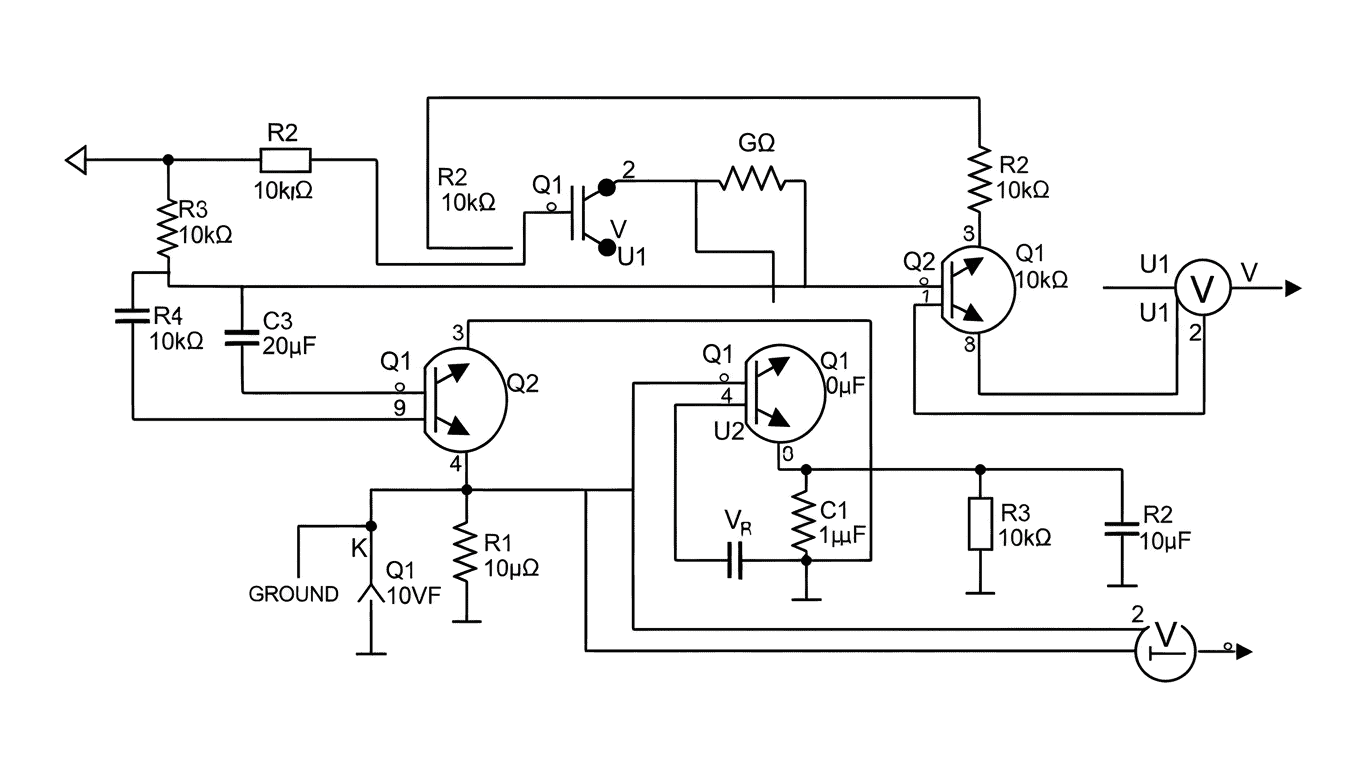

An 8 Pin Time Delay Relay Wiring Diagram serves as a blueprint for connecting a specific type of relay that introduces a controlled delay between the energization or de-energization of a control signal and the activation or deactivation of its output contacts. Unlike simpler relays, these devices offer programmable delays, making them invaluable for tasks that cannot tolerate immediate action. They are the silent orchestrators of sequential operations, preventing premature starts or ensuring proper settling times before a subsequent step is initiated.

The eight pins on these relays typically break down into several key categories, facilitating a range of functionalities. Understanding these pins is the first step to mastering the 8 Pin Time Delay Relay Wiring Diagram. Generally, you will find:

- Power Input Terminals: For supplying the control voltage to the relay.

- Control Input Terminals: Where the signal that triggers the timing function is applied.

- Output Contacts: These are the switches that the relay controls, and they are what ultimately switch power to your loads. Time delay relays usually have a set of normally open (NO) and normally closed (NC) contacts.

- Adjustment Terminals (optional): Some models allow for external adjustment of the time delay via potentiometers or other components.

The applications of an 8 Pin Time Delay Relay Wiring Diagram are extensive and span across various industries. Consider these examples:

- Motor Start-Up: Delaying the engagement of a motor to allow other components to reach operating speed or to prevent power surges.

- Lighting Control: Implementing timed sequences for industrial or security lighting, such as delaying the turning off of lights after a certain period.

- Process Automation: Ensuring that specific steps in a manufacturing process occur in the correct order and with appropriate pauses.

- HVAC Systems: Coordinating the operation of fans, compressors, and other elements to optimize performance and prevent damage.

The correct interpretation and implementation of an 8 Pin Time Delay Relay Wiring Diagram are paramount to the safe and efficient operation of any electrical system.

If you're looking to get hands-on with implementing these relays, referring to specific diagrams provided by the manufacturer for your chosen time delay relay model is the most reliable approach. These manufacturer-provided resources will detail the exact pin assignments and expected behavior for your particular unit.