Navigating the intricacies of electrical components can sometimes feel daunting, especially when dealing with powerful machinery. This article aims to demystify the 7.5 Hp Baldor Motor Capacitor Wiring Diagram, providing you with a clear understanding of its function and how it plays a crucial role in the operation of your Baldor motor. Whether you're a seasoned technician or a DIY enthusiast, grasping the 7.5 Hp Baldor Motor Capacitor Wiring Diagram is key to efficient maintenance and troubleshooting.

Understanding the Role of Capacitors in Baldor Motors

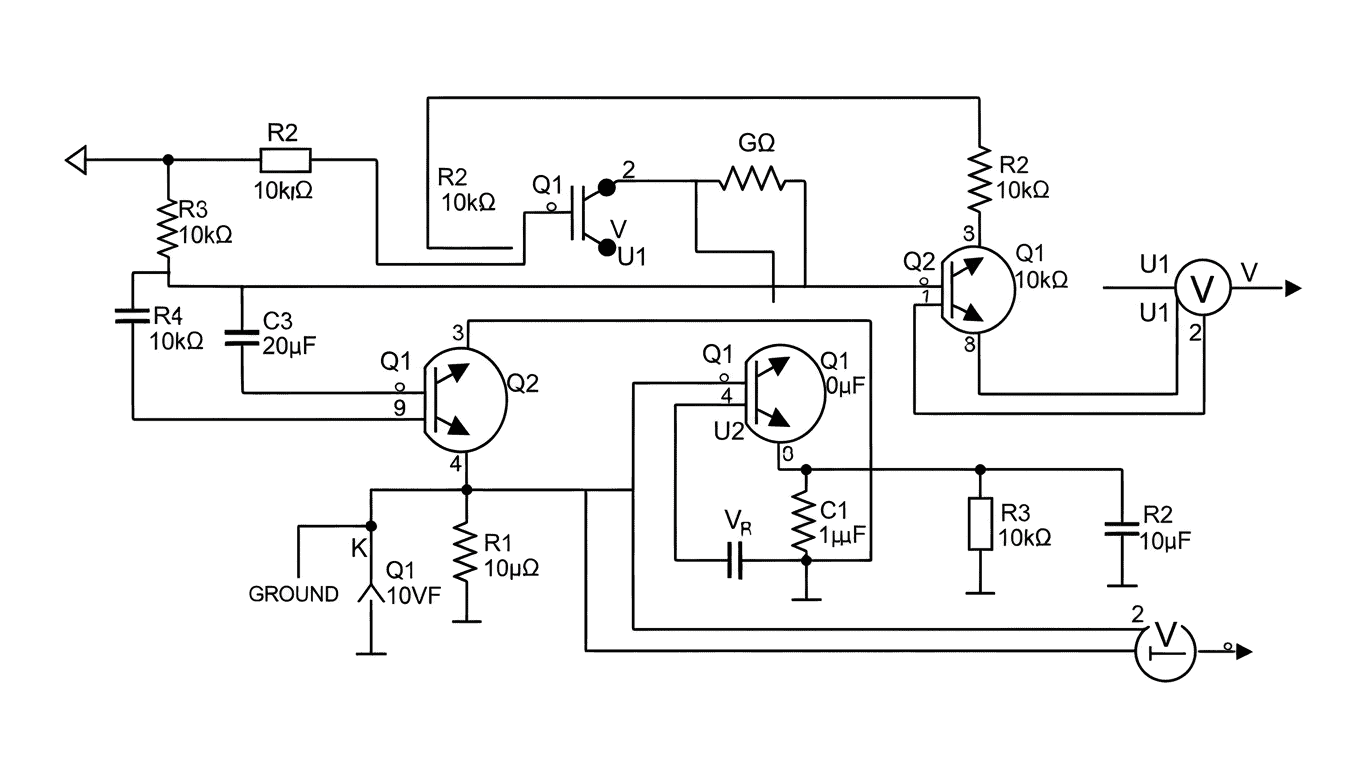

A 7.5 Hp Baldor motor, like many single-phase induction motors, relies on capacitors to initiate and maintain its rotation. Single-phase power, by itself, creates a pulsating magnetic field that isn't strong enough to get the motor spinning from a standstill. This is where capacitors come into play. They essentially create a phase shift in the electrical current, generating a rotating magnetic field that allows the motor to start and run efficiently. Without the correct capacitor configuration, as detailed in the 7.5 Hp Baldor Motor Capacitor Wiring Diagram, the motor might hum but fail to turn, or it might struggle to reach its full operational speed.

The 7.5 Hp Baldor Motor Capacitor Wiring Diagram will typically show two types of capacitors: a start capacitor and a run capacitor, though some configurations might only use one.

- Start Capacitor: This capacitor provides a significant boost of power for a brief moment to overcome the motor's inertia and get it spinning. It is only active during the starting phase and is then disconnected from the circuit.

- Run Capacitor: This capacitor remains in the circuit continuously while the motor is running. It helps to improve the motor's efficiency, power factor, and torque.

Understanding the 7.5 Hp Baldor Motor Capacitor Wiring Diagram is crucial for proper motor function and longevity . Incorrect wiring can lead to:

- Overheating of the motor.

- Reduced motor performance.

- Premature capacitor failure.

- Damage to motor windings.

| Component | Connection Point |

|---|---|

| Line Power (L) | Terminal 1 |

| Neutral Power (N) | Terminal 2 |

| Start Capacitor | In series with start winding, connected via centrifugal switch |

| Run Capacitor | In parallel with run winding |

To accurately identify and connect the capacitors for your specific 7.5 Hp Baldor motor, it is imperative to refer to the official 7.5 Hp Baldor Motor Capacitor Wiring Diagram provided by Baldor Electric. This official documentation is the most reliable source for ensuring correct installation and troubleshooting.